Heat up the nozzle and wipe it off if you have to.įor PLA, for beginners I would print on blue painter's tape, set the bed temperature at 55, and start with the hotend at 190. Make sure there's not a cooled off plastic booger hanging off the nozzle when you adjust it or you'll be way too high. Ideally, calibrate the bed by homing the printer, then remove power and adjust the bed screws until you can just slide a piece of paper under the head in all parts of the bed (move the head left and right and the bed front to back) - the paper should drag a little on the head. If it's just a round tube lying on the print bed then you need to raise the bed a little by adjusting the screws in the corners. When the first layer is being printed, ideally the extruded plastic will be somewhat flattened.

I don't much like the tape the MP Select comes with. Regardless of type, first put down some blue painter's tape.

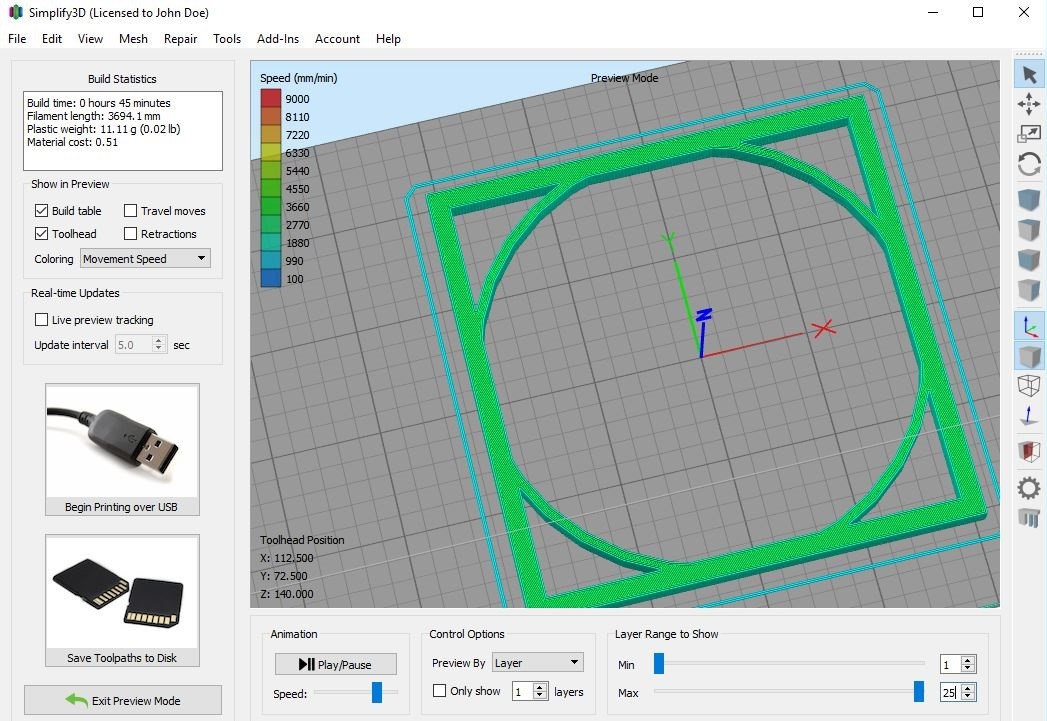

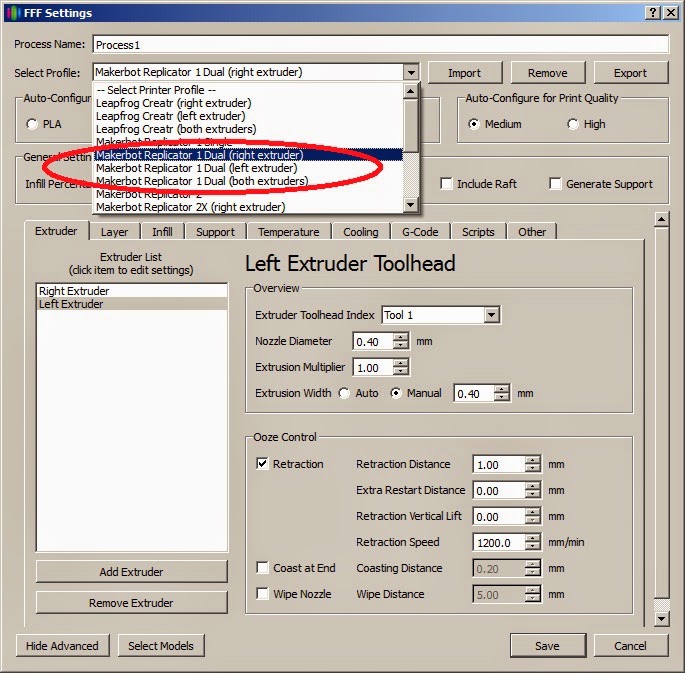

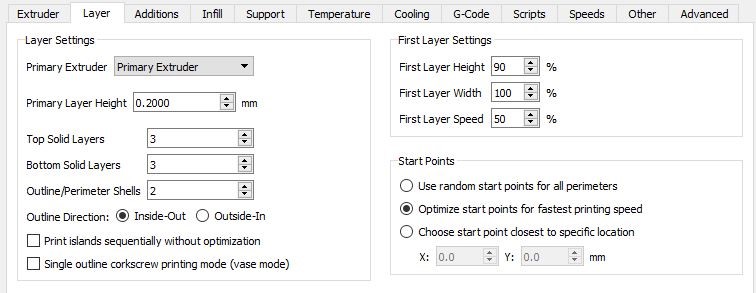

But to be honnest, I'm struggling with this printer for months.BEST ANSWER: You don't say what kind of filament, temperature of hotend or bed. To me, it looks like the steps are not concistent. I don't get it, I've tried to take the whole print-head apart and rebuild it. On the slicers side of things, I've tried all the main slicers (Slic3r PE, Prusa Control, Cura, Simplify 3D) all with default settings and with my settings. The first layers are perfect, but slowly the nozzle start to drag across the infill, when the print head reach a certain height and the nozzle is too close to the print, the extruder start to click and skip and the print is ruined. I've re-flashed the firmware, re-calibrate XYZ and the first layer. I've checked and adjusted the Z height, probe height, live Z value, extrusion multiplier, all the parts of the extruded (nozzle, heatbreak, ptfe tube). This time it's a problem with the nozzle dragging across infill and finally hitting the printed part. I'm back with another issue with my MK2s.

Nozzle dragging across infill and hitting print

0 kommentar(er)

0 kommentar(er)